“Direct to Garment” (DTG) is a digital printing technique used to print high-quality, full-colour images or designs directly onto fabric, typically on garments like t-shirts, hoodies, and other apparel items. DTG printing is an alternative to traditional screen printing and heat transfer methods. Here are some key features and benefits of DTG printing:

- Full-Colour Printing: DTG printing allows for full-colour, high-resolution printing. It can reproduce intricate details and vibrant colours, making it ideal for complex and colourful designs.

- Photo-Realistic Prints: This method can produce photo-realistic images with fine details, shading, and gradients, which can be challenging with other printing techniques.

- Customisation: DTG printing is well-suited for customisation. It is commonly used for printing one-off or small batches of custom garments, such as personalised shirts, promotional products, or unique designs.

- Quick Turnaround: DTG printing is relatively fast compared to traditional methods like screen printing, which require setting up screens and multiple passes for each colour. DTG printers can produce a full-colour design in a single pass.

- Soft and Comfortable Prints: The ink used in DTG printing is water-based, eco friendly and soaks into the fabric’s fibers, resulting in a soft and comfortable feel. The printed design does not have a heavy or rubbery texture on the fabric.

- Reduced Set-Up Costs: Unlike screen printing, which involves significant setup costs and labour for creating screens and colour separations, DTG printing has minimal setup requirements, making it cost-effective for small runs.

- Eco-Friendly: DTG printing is considered environmentally friendly because it uses water-based inks, producing less waste and reducing the need for harmful chemicals.

It’s worth noting that while DTG printing offers many advantages, it may not be as cost-effective as traditional methods for large production runs. DTG technology has gained popularity in the custom apparel industry and is commonly used for producing personalised clothing, custom merchandise, limited-edition designs, high quality premium printing and is a sought after method for print on demand companies and drop shippers.

Typical Use

1 to 5000 volume jobs.

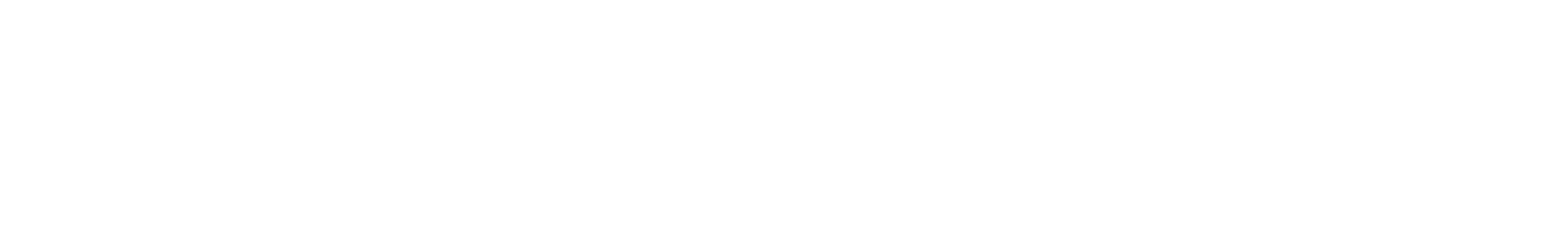

Key Benefits

No setup charge.

No minimum order quantity.

Unlimited colours making it cost effective for full-colour designs.

Eco-friendly use of natural water-based inks.

The inks absorb into the garment, making it durability and less prone to cracking, stretching and fading.

Fast production time.

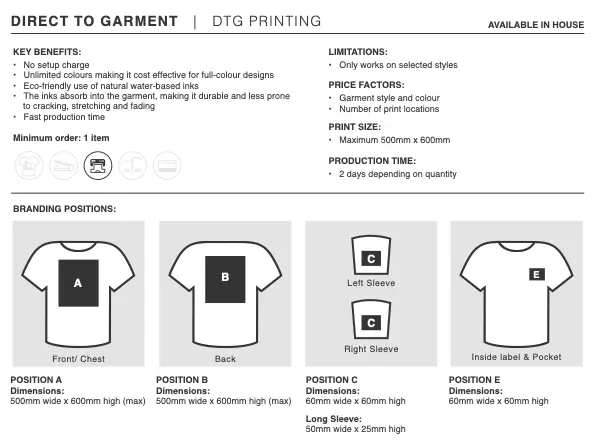

Print size

Maximum 350mm X 450mm

Limitations

Only works on selected styles/colours.

Production Time

3 to 5 working days depending on quantity.

Price Factors

Garment style and colour.

Number of print locations.

Order Process

1. Order

Order your desired Vic Bay garments as per usual.

2. Artwork

Send us your artwork in one of the following formats: PNG, JPEG, TIFF and PDF with a minimum resolution of 300dpi.

3. Approval

You will receive a copy for approval, once approved and payment is received you will receive a delivery date.

We also offer screen printing if DTG printing doesn’t serve your needs.

Contact us to speak to your sales executive to place an order today.